Book Appointment Now

Firetrace Suppression System Installation, Commissioning & Maintenance

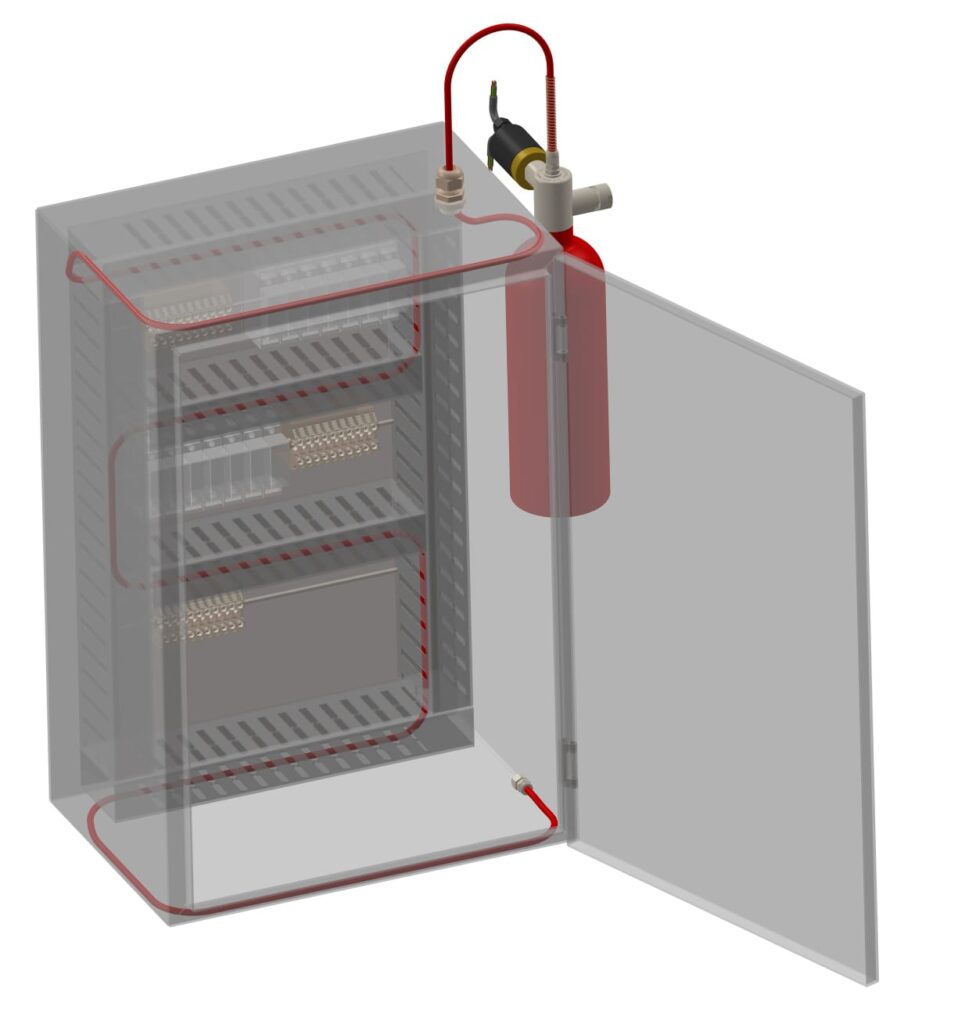

Firetrace is a targeted, self-activating suppression system designed for small, high-risk enclosures. Our certified installation team understands the critical nature of these systems. We don’t just fit the system; we engineer the fire protection solution for your specific application, ensuring optimal detection tube routing and agent discharge for instant fire knockout at the source.

Custom Design: Tailored layouts for takeaway kitchens, server racks, control panels, CNC machinery, and vehicle engine bays.

Certified Engineers: Installation carried out by factory-trained specialists for compliance and reliability.

Minimal Disruption: Efficient installation practices to keep your downtime to an absolute minimum.

SolveFireSafety is your certified partner for end-to-end Firetrace system management, ensuring your sensitive machinery, electrical cabinets, and vehicles receive immediate, targeted protection at the source of the fire.

We provide a full lifecycle service that adheres strictly to manufacturer guidelines and relevant national fire safety standards, giving you unparalleled peace of mind.

Installation & Design: We don’t use a one-size-fits-all approach. Our certified technicians custom-design the direct or indirect low-pressure system layout to suit the specific risk, whether it’s a server rack, CNC machine, or engine compartment. We guarantee a precision fit for optimal fire detection tube routing and rapid agent discharge.

Mandatory Commissioning: Following installation, commissioning is a critical verification step. This process ensures the system is fully operational, pressure-tested, and performs exactly as designed. Upon successful completion, we issue an official Commissioning Certificate, essential for insurance purposes and regulatory compliance.

Maintenance & Certification (Key to Reliability): Fire suppression systems demand routine checks. We rigorously inspect the cylinder pressure, detection tubing integrity, agent levels, and all associated components. We then complete the necessary Schedule of Servicing/Testing documents and update your log book, ensuring your system remains certified and reliable 24/7.

Why choose us?

Targeted Expertise: We specialize in the unique requirements of Firetrace systems, handling clean agents, CO2, and wet chemical variations.

Compliance Documentation: We provide detailed service reports and essential regulatory documentation after every site visit.

24/7 Emergency Support: We offer a rapid response callout service for emergency repairs or post-discharge system recharges.

Asset Protection Focus: We protect the assets that matter most—minimizing downtime and maximizing protection for high-value equipment.

Frequently Asked Questions

What exactly is a Firetrace suppression system and where should it be installed?

Firetrace is a self-activating, pre-engineered fire suppression system designed for targeted, internal protection of small, high-risk enclosures or micro-environments. It operates using a patented, pressurized detection tube that automatically ruptures upon exposure to fire (typically around 110°C), discharging the suppression agent directly at the source.

Common installation areas include:

- Electrical control panels and switchgear

- Server racks and data cabinets

- CNC machinery and industrial equipment

- Engine compartments of vehicles, buses, and plant machinery

- Commercial kitchen hoods and fryers (in some specialized configurations)

Does a Firetrace system require an external power supply or a separate fire alarm panel?

The core Firetrace system is pneumatically operated and is a standalone device. It relies entirely on the pressure within the detection tubing, meaning it remains fully operational even during a power outage.

This self-activating design provides continuous protection independent of the building's main power supply. However, for enhanced safety and compliance, the Firetrace system can be seamlessly interfaced with an existing fire alarm system or equipment shutdown mechanism via a pressure switch.

What type of fire suppression agent does Firetrace use, and is it safe for electronics?

Firetrace systems are versatile and can utilize various fire suppression agents depending on the specific application and fire risk:

- Clean Agents (e.g., Novec™ 1230, FM-200™): These are commonly used for sensitive **electronics** (electrical cabinets, servers) as they leave zero residue, are non-conductive, and are safe for personnel in the protected space.

- Dry Powder or Wet Chemical: These agents are used for specific **high-hazard risks** like engine compartments in vehicles or certain commercial kitchen applications.

Our experts will always specify the correct agent for your specific enclosure to ensure effective suppression with minimal collateral damage to your critical assets.

How often does my Firetrace system need maintenance, and what standards must be followed?

To ensure continuous reliability and full compliance, your Firetrace system requires a rigorous maintenance regime:

- Visual Check (Recommended Quarterly): The system pressure gauge and detection tube should be visually checked by the site operator (Responsible Person) to ensure they are undamaged and within operating limits.

- Annual Servicing (Mandatory): A comprehensive service must be carried out annually by a **competent, certified engineer**. This is mandated to comply with standards such as **BS 5306-3** (Commissioning and maintenance of portable fire extinguishers and fixed systems).

- Extended Service/Discharge Testing: Dependent on the agent used, a discharge test and overhaul may be required at 5 or 10-year intervals (e.g., 5 years for dry powder systems).

We provide all required certification and log book documentation following every service visit, ensuring your full compliance.

What is the difference between Direct and Indirect Firetrace systems?

This refers to how the **extinguishing agent is delivered** within the enclosure:

- Direct Release: The detection tube itself ruptures at the point of the fire, and the agent is discharged directly through that hole onto the fire. This method is faster and highly efficient for **small enclosures** (micro-environments).

- Indirect Release: The detection tube is used only for detection. When it ruptures, it triggers a valve that discharges the agent through separate, fixed **distribution nozzles** plumbed into the protected area. This method is typically used for **larger or more complex enclosures** where broader distribution is needed.